Fault Detection & -Localization

The detection/localization of cable faults is a very traditional application of time domain reflectometers (TDR) and also the reason for calling these devices 'cable radars'. Sequid's TDR devices (DTDR-65/STDR-65) exhibit a very fast step signal with a rise time of <65ps. This allows for a high spatial resolution enabling the user not only to detect faults (e.g. transmission line breaks, short-circuits, faulty solder joints, insufficient connected connectors) in small electrical and electromechanical components, but also to localize them with a resolution <10mm.

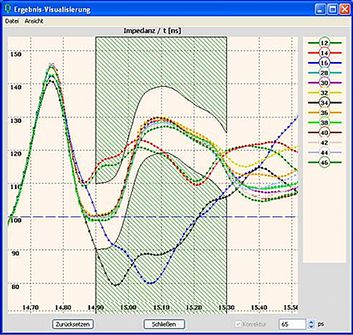

TDR fault detection and localization with tolerance mask.

The measurement principle bases on applying a TDR step signal with a very fast rising edge to a device under test (DUT). The DUT measurements are characterized by means of an individual tolerance mask (see figure above). The mask is pre-determined by performing TDR measurements with 'OK'-samples (often called 'golden samples'). An 'OK'/'NOK' classification finally is made by determining if the DUT measurement is within the given tolerance, what is done automatically by the software. The user can see on a glance, whether the DUT is within the specification or not.

Automated TDR & controlled Impedance Measurements

Often the controlled impedance measurements and fault detection is part of the quality inspection procedure and therefore has to be performed (semi-) automatically. The Sequid TDR experts own long-lasting expertise of integrating controlled impedance trace & TDR measurements in your quality management system. The integration includes the hardware adaptation (incl. high frequency multiplexing) as well as the software implementation and interfacing. For further information, please contact our high frequency experts.